|

[?]Subscribe To This Site

|

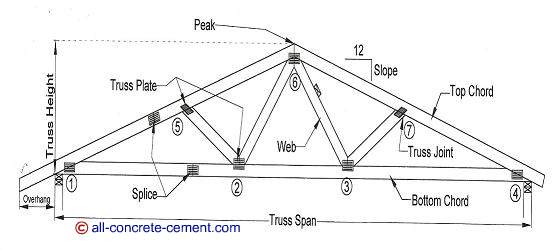

Roof Truss DesignIn general, residential roof truss design or building roof trusses are in most cases truss manufacturers' responsibility. Prefabricated roof trusses are the term that is commonly used by architects and engineers to specify wood trusses on construction plans. The other involvement of building designers with trusses are specifying the shapes and slope that’s end of the involvement of the building designers when it comes to trusses. For wood truss calculations click here or go here for steel truss calculations. Truss manufacturers' responsibility are to create roof truss plans and provide truss calculations as well as roof truss diagrams not only to help with manufacturing of the trusses but also help the framers for setting roof trusses in place at the job site.The outward look of trusses are the responsibilities of architect, home owner, or draft person that ultimately determine the shape, slope, and span of the roof trusses. As far as the design of the actual trusses i.e. the material quantities and sizes, type of truss joint connections, number of truss joints, size and type of lumber to use, etc are the truss manufacturers' responsibility. Due to the liabilities involve with truss design and manufacture, all truss fabricators carry their own engineer and insurances that are totally independent of the engineer of record or architect. The roof truss diagram shown below is a typical wood truss used for homes, garages, sheds, carports, barns, commercial buildings, etc. Once the span and slope of the trusses are determined by the building designers, the truss manufacturer can then go to work and design the number of joints and size of materials to be used based on the roof live load and dead load.

The truss diagram above can be made to fit truss span anywhere from 10 to 40+ feet, though there is no limit. Depending on the truss span and design requirements by architect, the joints spacing can vary widely, sometimes the joints are pre-positioned by designers in order to fit certain design requirements. If for example a clear space is required in order for a duct work or any type of equipment to pass thru uninterrupted, the truss joint spacing may have to be at certain location to accommodate such design requirement. This type of requirement not only affects the joint spacing but may also alter the type and size of material to be used, and in some cases will affect the roof slope as well. For information about how the loads for roof truss construction are determined click here. and here. To learn how the load are distributed to the truss joints go here. Back to roof truss design |

|