Roof trusses diagrams

by Nathy Cabrera Orquinaza

(Malolos City, Bulacan, Philippines)

Question:

Answer:

Hi Nathy,

Roof trusses are difficult to build at the job site because they require tedious calculations. On top of that the assembling procedures and the intensive labor that involves make building trusses at the construction site less appealing.

Most contractors and home owners here in the States take their plans to truss manufacturers to have them built which include all the truss analysis to meet code requirements prior to delivering them to the job sites for installation.

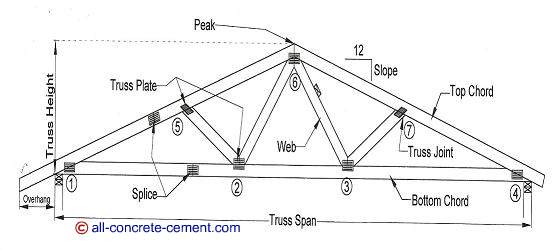

The detail below is an example of a typical roof truss about 12 to 25 feet clear span.

From the diagram, the points where the web meet with the top and bottom chord are called joints. These joints are numbered to help with the joint calculations and connections design.

Imagine if the truss you are trying to build is 80 to 100 feet long - you will be looking at 20 to 30 joints. If you have 60 trusses to build, there will be 1200 to 1800 different joints to be analysed.

Most of these joints are the same if the forces and building configuration are symmetric a lot of the trusses are the same which will make the calculations and assembling much easier.

For a simple truss to build such as the diagram above, it is best to sketch out the truss first. If the truss can be drawn in to scale in such program as auto cad, it will make determining each truss chord member's lengths and angles much easier which will make the rest of the work faster.

One of the challenges of constructing trusses at job sites is there is no way to determine the strength of joints. This problem is especially critical at areas where snow load is an issue. The joint forces may easy to determine but but figuring type of connection to withstand those forces will be difficult.

Good luck

Tonga

Join in and write your own page! It's easy to do. How? Simply click here to return to Got Question?.