|

[?]Subscribe To This Site

|

Monolithic SlabMonolithic slab is a term used in concrete slab construction to describe concrete structural elements such as footings, slabs, foundations, grade beams, piers, and columns being poured simultaneously. A monolithic cement slab or diy concrete slab not only applies to concrete cast on the ground, it also applies to suspended slab. Even though a suspended concrete slab is above ground level, the use of shoring materials enables the pouring concrete slab monolithically with concrete beams and columns.

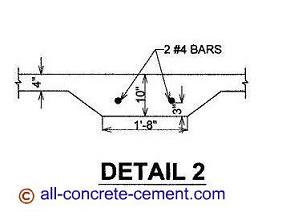

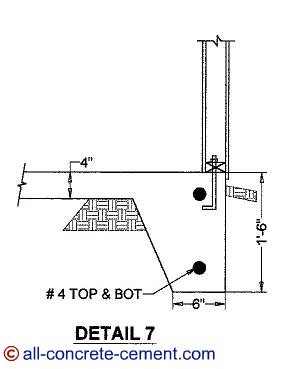

Both details 2 and 7 below are examples of monolithic concrete slab. Detail 7 is a typical cast in place concrete interior footing. Typically this detail is used at bearing walls that carry floor and roof loads. Non-bearing walls, since they carry no floor or roof loads are placed directly on top of the slab. Due to intensity of labor involve with constructing interior footings, more and more designers are using the monolithic concrete slab approach. Detail 7 is another form of monolithic slab where the footing or foundation, depending on how you look at it is intended to be poured monolithic with cement slab. The anchor bolts are shown on detail 7 because the thickened edge occur at the structure’s perimeter making it easy to reach and install the anchor bolts are the cement is poured and level. On other hand interior footings such as shown in detail 2 are not reachable to install anchor bolts. In most cases interior footings are intended to carry vertical loads only but if those bearing walls were designed as shear walls, the anchor bolts will need to be included. Should this be the case I recommend using expansion bolts and drill them after the concrete slab is done.

The photo show actual formwork for a house to be poured monolithically, very similar to detail 7. In the photo item#2 is a 2x6 that run opposite to the exterior 2x12 exterior form. This is how you can form a curb wall all around the perimeter to be above the floor slab. Most builders myself included prefer the bottom plate of wall framing to be above the slab. When pouring concrete slab such as the monolithic slab in the photo fill the bottom half all around first with dry mix 3 inch slump. As you fill the bottom half of the footing, by the time you get to where you started, the concrete should already start to set. This is done for two reasons: one it will lessen the hydro pressures exerted by the wet concrete on the perimeter form; two it will save concrete. With a dry mix at the bottom it will minimize concrete overflow thru small holes in the forms. This will help control the concrete waste. Back to monolithic slab From monolithic slab to all-concrete-cement.com Your Question or CommentWelcome! What Other Visitors Have SaidClick below to see contributions from other visitors to this page...

Monolithic construction of beam and slabs

Shoring Concrete Slab on Grade Not rated yet |

|