|

[?]Subscribe To This Site

|

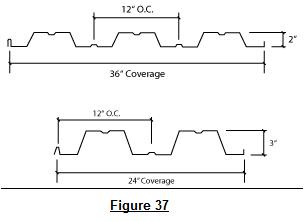

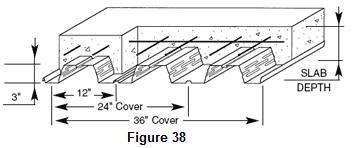

Composite Metal DeckComposite metal deck, steel floor decking, and concrete floor deck all refer to steel decking specifically for concrete floors. This steel deck is designed to support the concrete during the pour which will remain to be in place permanently. In order for these decks to be fully logged into the concrete they are designed with embossments so as to interlock with the concrete once poured and cured. It is the embossment that differentiates the metal deck for roof from metal deck intended for floor which will support concrete. The composite deck are typically supported by steel beams spaced between 10 and 14 feet depending on the deck gauge, heavier gauge span longer.The decks are connected to the beams with puddle welds. The spacings of these puddle welds are dependent on the amount of shear forces generated by seismic or wind load. In order to prevent the decks and the floors from sliding, these puddle welds provide the shear resistance needed to stabilize the floors laterally.

Nelson studs are very important component of composite concrete floors. Because these studs are welded on top of the steel beams, they provide shear resistance the same way puddle welds do. That's why nelson studs are also known as shear connectors. In addition to shear resistance, these nelson studs provide the necessary bonding interlocking the concrete and steel making them one structural element to support floor loads vertically and lateral seismic and wild load. These nelson studs, in most cases, are 3/4 inch by 5 to 6 inches long. Most engineers specify them to be from 1/2 to 3/4 inches lower than the top of concrete. Back to the top |

|